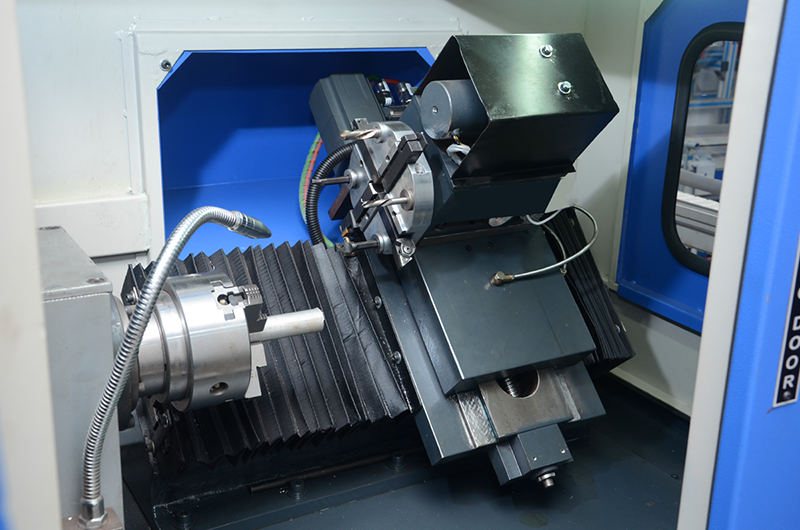

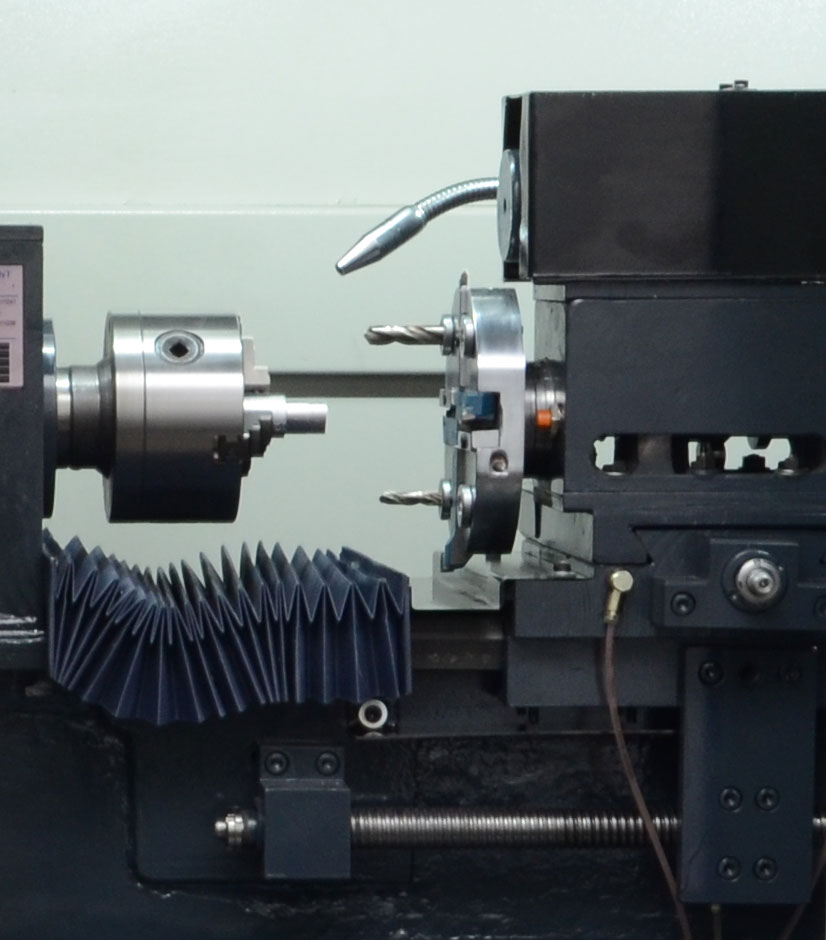

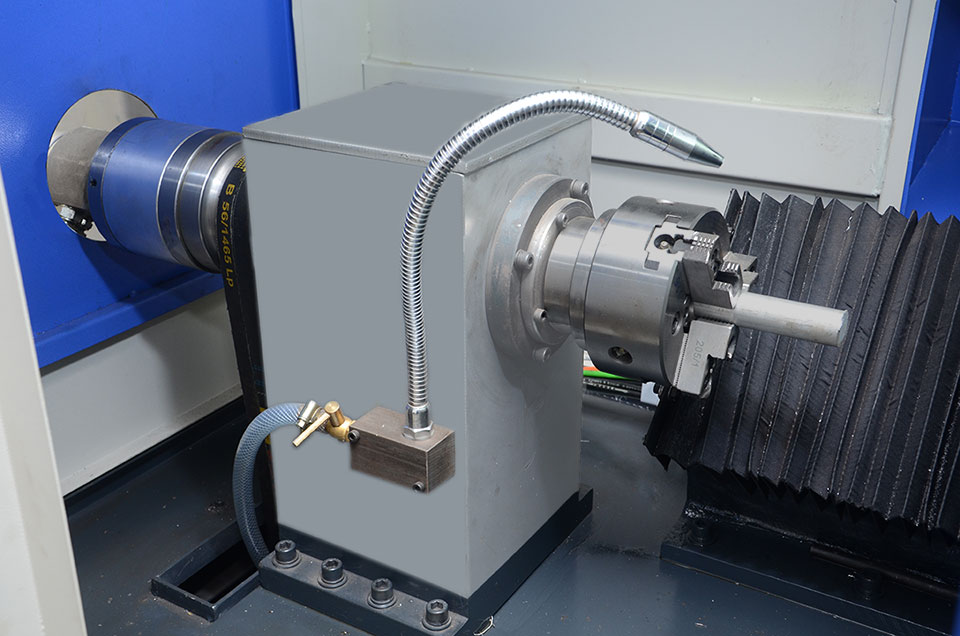

CNC Lathe Trainer

Features of CNC Lathe Trainer Machine

- Can work on Mild Steel

- Can be used for light production work

- Industrial Tool Changer (For Semiproduction Machines)

- Being used in Reputed tool rooms across India such as MSME Agra, IDTR Jamshedpur, MSME Coimbatore, IGTR Ahmedabad, IGTR Aurangabad, MSME Mumbai

- Authorised Distributors for Fanuc India products

- Industrial controllers from Siemens and Fanuc

- Three Dimensional Simulation as well as dynamic machining

Prestigious Customers of CNC Lathe Trainer Machine

- Maruti Suzuki Capability Development Center – Manesar

- IIT (Delhi)

- MSME Agra

- Indo German Tool Room – Ahmedabad

- Indo German Tool Room – Aurangabad

- Indo Danish Tool Room – Jamshedpur

- GCE Bilaspur

- NIT Warangal

- MSME Mumbai

- MSME Coimbatore

- Amity University – Greater Noida

Specifications of CNC Lathe Trainer Machine

| CLT 100 | SLT 100 Servo | |

| CNC Lathe Trainer Machine Details: | ||

| Bed Type | Flat / 45 Degrees Slant | Flat / 45 Degrees Slant |

| Keyboard Type | Fanuc Emulated / Standard | Fanuc Emulated / Standard |

| Chuck Size | 100 mm (Dia) | 100 mm (Dia) |

| Chuck Type | Hydraulic / Manual | Hydraulic / Manual |

| Maximum Turning Diameter | 50 mm | 50 mm |

| Maximum Turning Length | 250 mm | 250 mm |

| Center Height | 100 mm | 100 mm |

| Swing over Cross Slide | 80 mm | 80 mm |

| Swing Over Bed | 200 mm | 200 mm |

| Distance between Centre | 320 mm | 320 mm |

| CNC Controller Details: | ||

| Controller | CutViewer-United Kingdom with Emulation of Fanuc, Siemens , Traub and Heidenhain |

CutViewer-United Kingdom with Emulation of Fanuc, Siemens , Traub and Heidenhain |

| Control System | PLC Based Control System | PLC Based Control System |

| Operating Software | CutViewer – United Kingdom | CutViewer – United Kingdom |

| Accuracy: | ||

| Positioning | 0.010 mm | 0.005 mm |

| Repeatability | +- 0.015 mm | +/- 0.010 mm |

| Resolution | 0.010 mm | 0.001 mm |

| Spindle: | ||

| Spindle Motor | AC Motor | AC Motor |

| Spindle Motor Capacity | 2 HP | 3 HP |

| Spindle RPM | 100 to 3000 RPM with VFD | 100 to 3000 RPM with VFD |

| Spindle Nose Taper | A 2-3 / MT 3 | A 2-3 / MT 3 |

| Hole Through Spindle | 20 mm | 20 mm |

| C Axis (Optional) | C Axis with Brake | C Axis with Brake |

| Axes | ||

| Axis Motor and Drive | Stepper Motor with Stepper Drives imported from Singapore | Servo Motor with Servo Drives (Mitsubishi / Siemens / Fuji) |

| X Axis Travel | 100 mm | 100 mm |

| Z Axis Travel | 280 mm | 280 mm |

| Ball Screw X / Z | Ø25 x 5 – C4 Class | Ø25 x 5 – C3 Class |

| Feed Rate | 0 to 1,200 mm/min | 0 to 5,000 mm/min |

| Rapid Travel | 1,200 mm/min | 0 to 5,000 mm/min |

| Turret and Tooling: | ||

| Turret Type | Automatic | Automatic |

| Number of Stations | 8 | 8 |

| Tool Cross Section | 16 mm x 16 mm | 16 mm x 16 mm |

| Boring Bar Size | 16 mm | 16 mm |

| Tailstock: | ||

| Tailstock Base Stroke | 200 mm | 200 mm |

| Tailstock Quill Stroke | 100 mm | 100 mm |

| Tailstock Actuation | Hydraulic / Manual / Electrical | Hydraulic / Manual / Electrical |

| Miscellaneous: | ||

| Lubrication | Automatic | Automatic |

| Coolant | Automatic | Automatic |

| FMS Compatibility | Provided | Provided |

| Real Time Toolpath Simulation | Provided | Provided |

| Dimension in mm | 1480 x 800 x 1200 mm | 1480 x 800 x 1200 mm |

| Power Supply | 230V, Single Phase | 415V, +-2% 50 Cycles, 3 Phase |

- PLC based technology which is much more advances than PC (I/O Card) based technology generally used in trainer machines

- Emulation of Emulation of Fanuc, Siemens , Traub as well as Heidenhain controller

- CAM Programs (NC Codes) Generated from any leading CAD CAM Software such as MasterCAM, NX CAM, solidworks, Solid EDGE, EDGE CAM can be directly executed on the Hytech CNC Trainer Machines

- Indigenously designed & manufactured patterns & high quality FG32 grade castings

- Ergonomically designed machine

- 8 Station automatic turret

- Option of Flat Bed as well as 45 Degree Slant Bed

- Floor mounted machine with minimum weight of 50 Kg

- C3 class ground ball screws

- Option of Hydraulic chuck (135mm and above) as well as Hydraulic tailstock

- Automatic Lubrication and Automatic Coolant

- Fanuc Emulated Industrial grade MOP

- Option of Metallic telescopic bellows

- Option of MPG (Manual Pulse Generator)

- AC Motor spindle with power ranging from 2HP to 5HP

- Air Mist Lubrication (Optional)

- Provision of software as well as hardware overtravel limits to avoid any accident