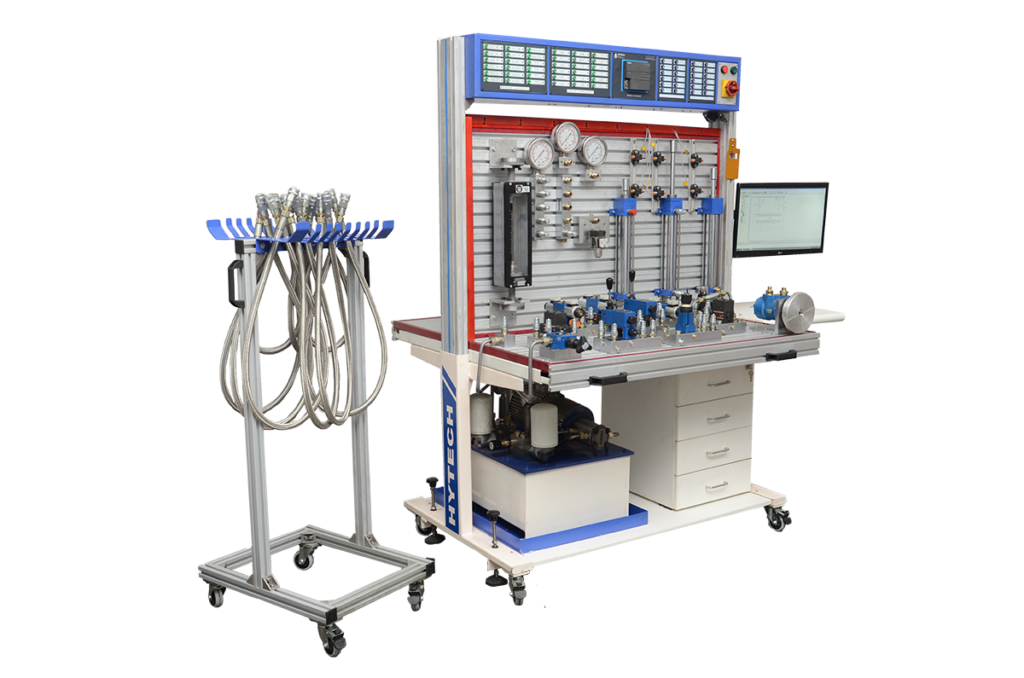

COMPUTER CONTROLLED ELECTRO HYDRAULIC TRAINER KIT WITH PLC

Key Features

- Simulation Mode

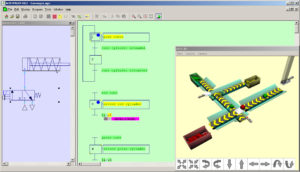

- Software from IRAI France

- Complete Flexibility in PLC operation

- Online Simulation of electro Hydraulic circuits

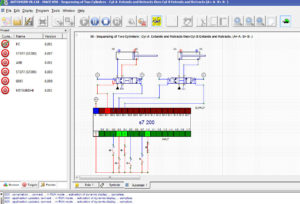

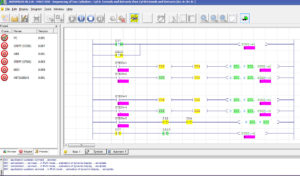

- Dynamic Ladder Diagram Updation

- Online simulation and updation of PLC Programs

- Completely controlled through computer / software

- Compatible with Siemens / Allen Bradley / Mitsubishi PLC

- Aluminium Alloy mounting panel for quick mounting and dismounting

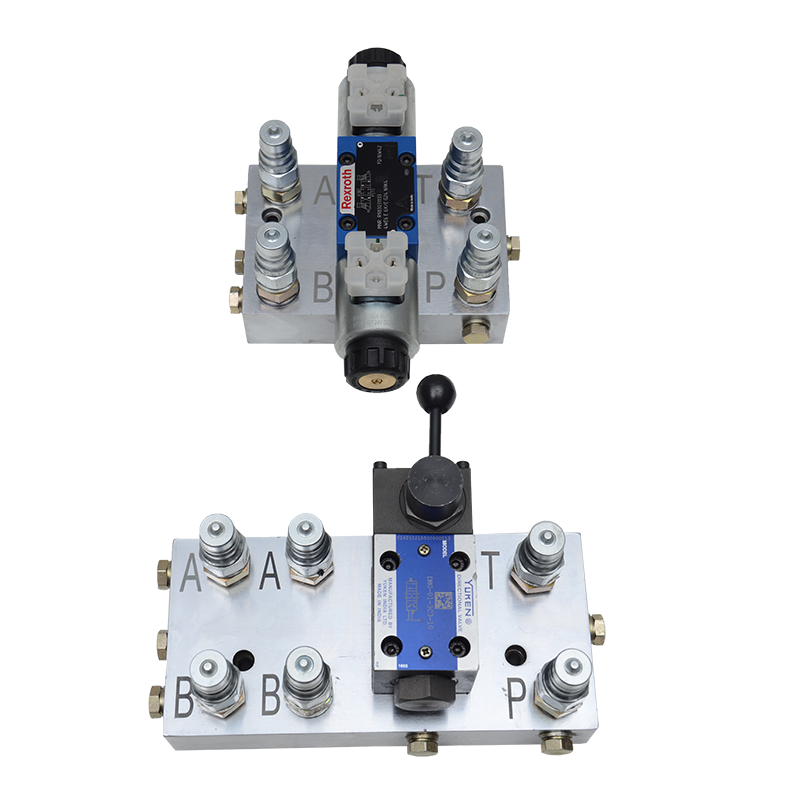

- Hydraulic components from Reputed brands such as Rexroth / YUKEN / EATON

- Hydraulic System Test pressure of 70 Bar and continuous operating pressure of 40 Bar

- Hydraulic circuits can be designed in software and the same can bedemonstrated on training kit

Features of Basic Hydraulic Trainer Kit

- Introduction to Hydraulics

- Fundamentals of Hydraulics

- Basic Requirement of Hydraulics

- Introduction to Hydraulic Components

- Introduction to hydraulic symbols and circuits

- Simulation of Hydraulic Circuits on AutomSIM Software

Prestigious Customers of Electro Hydraulic Trainer Kit

- Maruti Suzuki CDC(Capability Development Center)

- Ministry of MSME

- Indo German Tool Room (IGTR)

- IL&FS – National Skill Development Center

- National Institute of Technology – Warangal

- MSME Mumbai

List of Components

| List of Components for Electro Hydraulic Training Kits (Basic and Advance) | |||

| Component | Quantity | Make | |

| Basic | Advance | ||

| Trolley (Aluminum Channel) with frame & caster wheels with Brake (Loadcapacity: 400 Kg) | 1 | 1 | Reputed make |

| Hydraulic tank with 30 Litre capacity, Oil cleanliness: Level 8 (With suction filter and return line filter) | 1 | 1 | Repued make |

| Variable Frequency Drive for studying pump characteristics | × | 1 | Siemens |

| Three Phase flange mounted electric motor 2 HP -1500 rpm | 1 | 1 | Siemens |

| Pressure Gauge 0 to 100 Bar. Glycerin filled | 3 | × | Baumer / Burdon make |

| Push to read Pressure Gauge Isolator | × | 1 | Repued make |

| Gear Pump (Flow Rate: 8 LPM, Max Pressure: 70 Bar) | 1 | × | Dowty / Yuken / Rexroth |

| Vane Pump (Flow Rate: 6 LPM, Max Pressure: 140 Bar) | × | 1 | Yuken / Rexroth / Eaton |

| Hydraulic Motor Bidirectional . | 1 | 1 | Eaton / Yuken / Danfoss |

| Pressure Relief Valve (Direct operated relief valve) | 1 | 2 | Yuken / Rexroth |

| Flow Control Valve (Non Pressure Compensated) with Check Valve . | 2 | 2 | Yuken / Rexroth / Eaton |

| Flow Control Valve (Pressure Compensated) with Check Valve | 1 | 1 | Yuken / Rexroth / Eaton |

| Pressure Sequence Valve | 1 | 1 | Yuken / Rexroth / Eaton |

| Pressure Reducing Valve | × | 1 | Yuken / Rexroth / Eaton |

| Four way Two position manually operated direction control valve | 1 | 1 | Yuken / Rexroth / Eaton |

| Four way Three position manually operated direction control valve – Tandem Center | 1 | 1 | Yuken / Rexroth / Eaton |

| Four way Three position manually operated direction control valve – Closed Center | × | 1 | Yuken / Rexroth / Eaton |

| Single Acting Cylinder (Stroke: 100mm, Dia: 25mm, Test Pressure: 70 Bar) | 1 | 1 | Rexroth / Eaton / SMC |

| Double Acting Cylinder (Stroke: 200 mm minimum Test Pressure 130 Bar) | 1 | 2 | Rexroth / Eaton / SMC |

| Check Valve Direct Operated | 1 | 1 | Yuken / Rexroth / Eaton |

| Single Pilot Operated Check Valve | × | 1 | Yuken / Rexroth / Eaton |

| Needle Valve | × | 1 | Yuken / Rexroth / Eaton |

| Pressure Switch | × | 1 | Yuken / Rexroth / Eaton |

| Four Way Three Position Double solenoid operated direction control valve | × | 3 | Yuken / Rexroth / Eaton |

| Four Way Two Position Single solenoid operated direction control valve | × | 1 | Yuken / Rexroth / Eaton |

| Proximity Sensors (Test Voltage 30 V DC max) | × | 8 | Omron / Contrinex |

| Electrical control panel with all safety precautions and 230 Volts short circuit protection safety as per DIN standard | × | 1 | Reputed make |

| DC Power supply with modulator and rectifier | × | 1 | NHP / Omron |

| PLC with 18 Input and 12 Output with Modbus communication and PLC Ladder download facility | × | 1 | Siemens (S7 200 Smart) |

| Intel Mother board Computer with 21 inch LED Monitor with Bluetooth keyboard and mouse | × | 1 | Reputed make |

| Automgen (IRAI France) – Hydraulic Circuit Simulation Software with Dynamic PLC Ladder updation facility | × | 1 | IRAI France |

| Complete trainer kit can be operated directly from software | |||

| Automgen (IRAI France) – Hydraulic Circuit Simulation Software | 1 | × | IRAI France |

List of Experiments

| List of Components for Electro Hydraulic Training Kits (Basic and Advance) | |||

| Experiment No | Name of the experiment | Basic | Advance |

| 1 | Fundamental of pressure and force | YES | YES |

| 2 | Fundamental of flow rate, velocity, work and power | YES | YES |

| 3 | Introduction of control valves | YES | YES |

| 4 | Study of pressure builtup in hydraulic circuit | YES | YES |

| 5 | Operation of single acting cylinder with 4/2 way DC valve | YES | YES |

| 6 | Operation of double acting cylinder with 4/2 way DC valve | YES | YES |

| 7 | Operation of double acting cylinder with 4/3 way DC valve | YES | YES |

| 8 | Operation of hydraulic motor with 4/2 way DC valve | YES | YES |

| 9 | Operation of hydraulic motor with 4/3 way DC valve | YES | YES |

| 10 | Introduction of flow control valve | YES | YES |

| 11 | Speed control of double acting cylinder | YES | YES |

| 12 | Speed control of hydraulic motor | YES | YES |

| 13 | Meter in speed control circuit | YES | YES |

| 14 | Meter out circuit | YES | YES |

| 15 | Bleed off circuit | YES | YES |

| 16 | Introduction of sequence valve | YES | YES |

| 17 | Introduction of pressure reducing valve | YES | YES |

| 18 | Two cylinders in series | YES | YES |

| 19 | Two cylinders in parallel. | YES | YES |

| 20 | Sequencing of hydraulic cylinder and motor | YES | YES |

| 21 | Sequencing of two hydraulic cylinders | YES | YES |

| 22 | Use of pressure reducing valve to vary clamping force | YES | YES |

| 23 | Introduction of check valve | YES | YES |

| 24 | Introduction of single pilot check valve | YES | YES |

| 25 | Cylinder position control by single pilot check valve. | YES | YES |

| 26 | Introduction of relay and solenoid | NO | YES |

| 27 | Introduction of sensors, limit switch | NO | YES |

| 28 | Inch control of double acting cylinder with solenoid valve | NO | YES |

| 29 | Inching control of hydraulic motor with solenoid valve | NO | YES |

| 30 | Introduction of PLC and PLC interface | NO | YES |

| 31 | Operation of single acting cylinder with 4/2 way single sol valve | NO | YES |

| 32 | Operation of double acting cylinder with single solenoid valve | NO | YES |

| 33 | Continuous operation of single acting cylinder with 4/2 way single sol valve – AND gate | NO | YES |

| 34 | Operation of single acting cylinder with single sol valve –OR gate | NO | YES |

| 35 | Operation of double acting cylinder with single sol. Valve –AND gate | NO | YES |

| 36 | Operation of double acting cylinder with double sol. Valve –OR gate | NO | YES |

| 37 | Operation of double acting cylinder with double sol. Valve –AND gate | NO | YES |

| 38 | Operation of double acting cylinder with double sol valve –NOR gate | NO | YES |

| 39 | Operation of double acting cylinder with double sol. Valve –NAND gate | NO | YES |

| 40 | Introduction of up counter | NO | YES |

| 41 | Introduction of down counter | NO | YES |

| 42 | Hydraulic motor will stop after 5 rotation | NO | YES |

| 43 | NAND gate operation with electrical switches double acting cylinder | NO | YES |

| 44 | Continuous operation of double acting cylinder with double solenoid valve | NO | YES |

| 45 | Sequencing of cylinders: (A+B+), (A-B-) | NO | YES |

| 46 | Operation of double acting cylinder with single solenoid valve with on time delay | NO | YES |

| 47 | Operation of double acting cylinder with double solenoid valve with on time delay | NO | YES |

| 48 | Continuous operation of double acting cyl. with double sol valve and down counter | NO | YES |

| 49 | Continuous operation of double acting cylinder with double sol valve and up counter | NO | YES |

| 50 | Sequencing of two cylinders: cylinder A extends and retracts then cylinder B extends and retract | NO | YES |

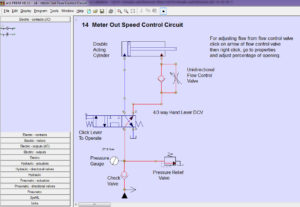

Hydraulic - Pneumatic Circuit Design and Simulation Software

IRAI Software Features

- Circuits can be simulated in the software

- Validity of Automgen software is Perpetual (Valid for lifetime)

- Library of the software contains more than 4000 hydraulic components

- Pneumatic Circuits can be designed / constructed in Automgen software

- Vital parameters such as flow rate / pressure can be tested at various points in the circuit

- The same circuits can be performed on Hytech – Pneumatic training kit directly through software

- PLC ladder diagram can be designed and dynamically updated i n Siemens / ABB / OMRON PLC

Optional Accessories

- Hydraulic Wall Charts

- Classroom Teaching Material

- Basic Level

- Advance Level

- Proportional and Servo Valves Modules with controller card