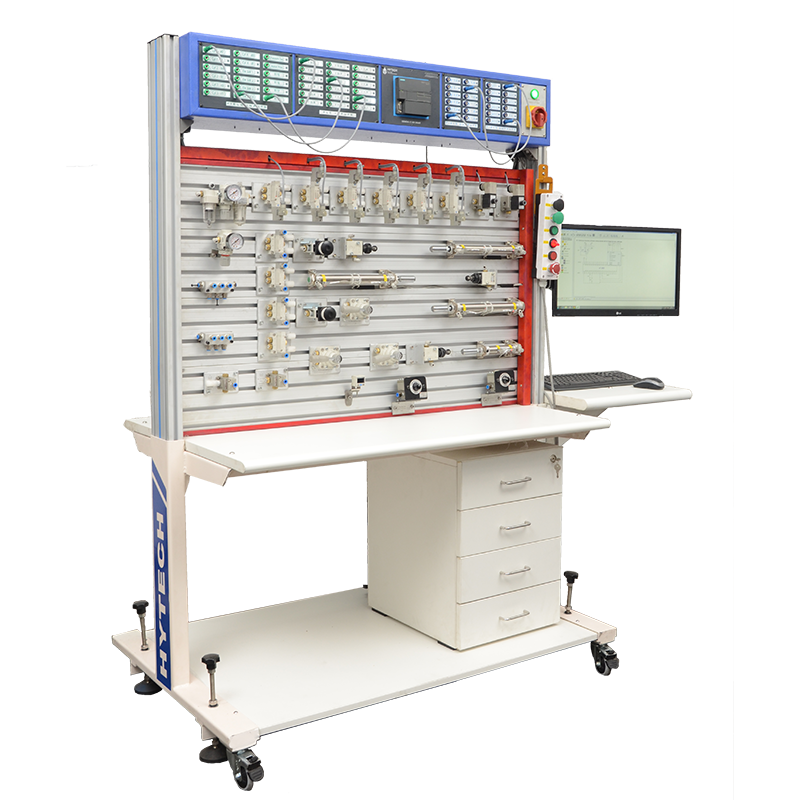

COMPUTER CONTROLLED ELECTRO PNEUMATIC TRAINER KIT WITH PLC

Key Features of Advanced Electro Pneumatic Trainer Kit

- Simulation Mode in electro pneumatic kits

- Software from IRAI France

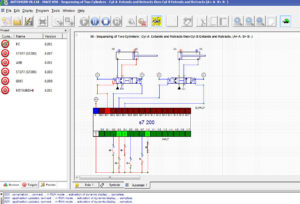

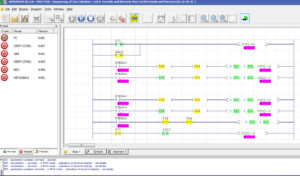

- Dynamic Ladder Diagram Updation

- Complete Flexibility in PLC operation

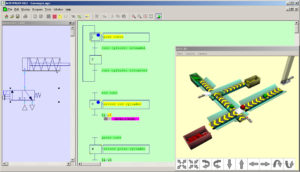

- Online Simulation of Pneumatic circuits

- Online simulation and updation of PLC Programs

- Authorized manufacturers, suppliers, exporters and dealers

- Completely controlled through computer / software

- Compatible with Siemens / Allen Bradley / Mitsubishi PLC

- Pneumatic components from Reputed brands such as SMC / Festo

- Aluminium Alloy mounting panel for quick mounting and dismounting

- Pneumatic circuits can be designed in software and the same can be demonstrated on training kit.

Features of Electro Pneumatic Trainer Kit

- Introduction to Pneumatics

- Fundamentals of Pneumatics

- Basic Requirement of Pneumatic

- Introduction to Pneumatic Components

- Introduction to Pneumatic symbols and circuits

- Simulation of Pneumatic Circuits on AutomSIM Software

Prestigious Customers of Electro Pneumatic Trainer Kit

- Maruti Suzuki CDC (Capability Development Center)

- Ministry of MSME

- Indo German Tool Room (IGTR)

- IL&FS – National Skill Development Center

- National Institute of Technology – Warangal

- MSME Mumbai

List of Components

| List of Components for Electro Pneumatic Training Kits (Basic and Advance) | ||||||

| Component | Quantity | Make | ||||

| Basic | Advance | |||||

| Trolley (Aluminum Channel) with frame & caster wheels with Brake (Loadcapacity: 400 Kg) | 1 | 1 | Reputed make | |||

| Compressor (50 LPM, 8 Bar, 24 Liter Tank Capacity) | 1 | 1 | Festo / Elgi | |||

| Single acting cylinder (Stroke: 50 mm, with One Way Flow Control Valve) | 1 | 1 | SMC / Festo | |||

| Double acting cylinder (Stroke: 200mm, with One Way Flow Control Valve) | 1 | 3 | SMC / Festo | |||

| Two Pressure Valve | 1 | 2 | SMC / Festo | |||

| Shuttle Valve | 1 | 3 | SMC / Festo | |||

| Quick Exhaust Valve | 1 | 1 | SMC / Festo | |||

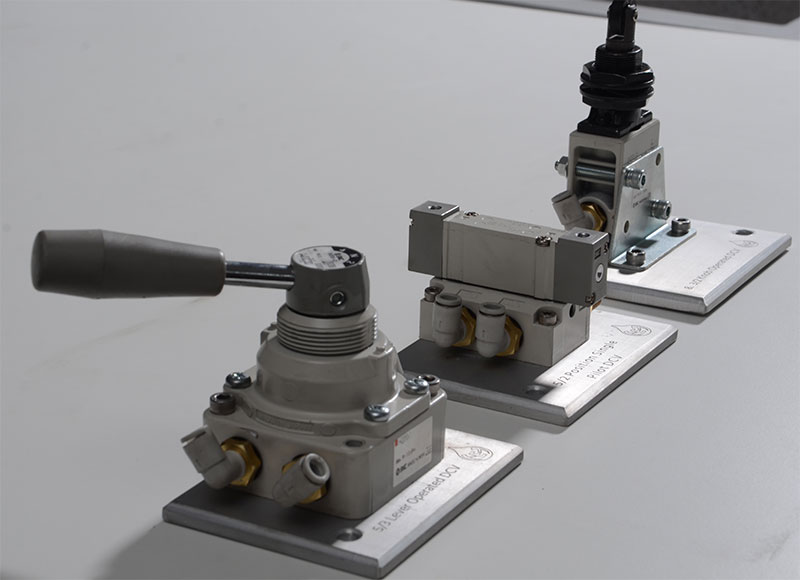

| Three Way Two Position Knob Operated Direction Control Valve (NC Type) | 2 | 2 | SMC / Festo | |||

| Three Way Two Position Roller Operated Direction Control Valve (NC Type) | 2 | 2 | SMC / Festo | |||

| Three Way Two Position Pilot Operated Direction Control Valve (NC Type) | × | 1 | SMC / Festo | |||

| Three Way Two Position Solenoid Operated Direction Control Valve (NC Type) | × | 1 | SMC / Festo | |||

| Push Button 3 Port Valve (NC Type) | 1 | 1 | SMC / Festo | |||

| Five Way Three Position Lever Operated Direction Control Valve | 1 | 1 | SMC / Festo | |||

| Five Way Three Position Double Solenoid Direction Control Valve | × | 1 | SMC / Festo | |||

| Five Way Three Position Double Pilot Direction Control Valve | 1 | 1 | SMC / Festo | |||

| Five Way Two Position Single Pilot Direction Control Valve | 1 | 1 | SMC / Festo | |||

| Five Way Two Position Double Pilot Direction Control Valve | 1 | 3 | SMC / Festo | |||

| Five Way Two Position Lever Operated Direction Control Valve | 1 | 1 | SMC / Festo | |||

| Five Way Two Position Single Solenoid Direction Control Valve | × | 1 | SMC / Festo | |||

| Five Way Two Position Double Solenoid Direction Control Valve | × | 4 | SMC / Festo | |||

| Three Way Two Position Time Delay Valve | × | 2 | SMC / Festo | |||

| Pneumatic motor | × | 1 | SMC / Festo | |||

| Two way Flow control valve | 1 | 1 | SMC / Festo | |||

| Vacuum generator with Vacuum clamp | × | 1 | SMC / Festo | |||

| FRL Unit (Filter Regulator & Lubricator) | 1 | 1 | SMC / Festo | |||

| Pressure Regulator | × | 1 | SMC / Festo | |||

| Pressure Switch with Digital set point | × | 1 | SMC / Festo | |||

| Pressure Line Manifold | 1 | 1 | SMC / Festo | |||

| Isolator Block | 1 | 1 | SMC / Festo | |||

| Electrical Control Panel 1 Set as per DIN standard | × | 1 | Reputed Make | |||

| Proximity Sensors (Test Voltage 30 V DC max) | × | 12 | Omron / Contrinex | |||

| Quick Push Pull connector | As Per Requirement | As Per Requirement | SMC / Festo | |||

| Plastic Tubing ( PU6) | As Per Requirement | As Per Requirement | SMC / Festo / Reputed Make | |||

| PLC with 18 Input and 12 Output with Modbus communication and PLC Ladder download facility | × | 1 | Siemens (S7 200 Smart) | |||

| Intel Mother board Computer with 21 inch LED Monitor | 1 | 1 | Reputed make | |||

| Automation Module | ||||||

| Press Application | ||||||

| Double acting cylinder (Stroke: 200mm, with One Way Flow Control Valve) | × | 1 | SMC / Festo | |||

| Proximity Sensors (Test Voltage 30 V DC max) | × | 1 | SMC / Festo | |||

| Mushroom Switch (Electrically Operated) | × | 2 | SMC / Festo | |||

List of Experiments

| List of Components for Electro Pneumatic Training Kits (Basic and Advance) | |||

| Sr. No. | Experiment | Basic | Advance |

| 1 | Study of Pressure Regulator and Air Lubricator | Yes | Yes |

| 2 | Physical fundamentals of Pneumatics | Yes | Yes |

| 3 | Study of Air Compressibility, Humidity Effect & FAD Calculation Of Compressor | Yes | Yes |

| 4 | Operation of Single Acting Cylinder with 3/2 Knob Operated DCV | Yes | Yes |

| 5 | Operation of Double Acting Cylinder by 5/3 Lever Operated DCV | Yes | Yes |

| 6 | Speed Control of Double Acting Cylinder with Flow Control (Meter In) | Yes | Yes |

| 7 | Speed Control of Double Acting Cylinder with Flow Control (Meter Out) | Yes | Yes |

| 8 | Pneumatic AND Gate Operation | Yes | Yes |

| 9 | Pneumatic OR Gate Operation | Yes | Yes |

| 10 | Operation of Single Acting Cylinder with AND Gate and 3/2 Way DCV | Yes | Yes |

| 11 | Operation of Pneumatic Motor with Speed Regulator | Yes | Yes |

| 12 | Operation of Pneumatic Motor with AND Gate and 3/2 Way Direction Control Valve | Yes | Yes |

| 13 | Operation of Double Acting Cylinder through Control Valve Momentary Trigger | Yes | Yes |

| 14 | Study of Quick Exhaust Valve | Yes | Yes |

| 15 | Study of Vacuum Clamp | Yes | Yes |

| 16 | Pick and Place with Vacuum Clamp | Yes | Yes |

| 17 | Operation of Two Cylinders in Series | Yes | Yes |

| 18 | Operation of Two Cylinders in Parallel | Yes | Yes |

| 19 | Operation of 5/2 Way Single Pilot Operated Direction Control Valve | Yes | Yes |

| 20 | Operation of 5/2 Way Double Pilot Operated Direction Control Valve | Yes | Yes |

| 21 | Two Step Speed Control of Double Acting Cylinder | Yes | Yes |

| 22 | Two Step Speed Control of Pneumatic Motor | Yes | Yes |

| 23 | Sequencing of D A Cylinder with Pneumatic Motor | Yes | Yes |

| 24 | Sequencing of D A Cylinder with S A Cylinder | Yes | Yes |

| 25 | Introduction to Pressure Switch | Yes | Yes |

| 26 | Introduction to Relay and Contactor | Yes | Yes |

| 27 | Introduction to Sensors | Yes | Yes |

| 28 | Introduction to Programmable Logic Controller review | Yes | Yes |

| 29 | Timer, Counter instructions in PLC | Yes | Yes |

| 30 | PLC Registers & Compare Function | Yes | Yes |

| 31 | Continuous Operation of Single Acting Cylinder with Single Solenoid Valve | No | Yes |

| 32 | Continuous Operation of Double Acting Cylinder with Single Solenoid Valve | No | Yes |

| 32A | Operation of Double Acting Cylinder with Single Solenoid Valve | No | Yes |

| 33 | Continuous Operation of Single Acting Cylinder with 3/2 Position Single Sol valve – AND Gate | No | Yes |

| 34 | Continuous Operation of Single Acting Cylinder with 3/2 Position Single Sol valve – OR Gate | No | Yes |

| 35 | Continuous Operation of Double Acting Cylinder with 5/2 Single Sol valve – AND Gate | No | Yes |

| 36 | Continuous Operation Of Double Acting Cylinder With 5/2 Double Solenoid Valve – OR Gate | No | Yes |

| 37 | Continuous Opertion Of Double Acting Cylinder With 5/2 Double Solenoid Valve – AND Gate | No | Yes |

| 38 | Continuous Opertion Of Double Acting Cylinder With 5/2 Double Solenoid Valve – NOR Gate | No | Yes |

| 39 | Opertion Of Double Acting Cylinder With 5/3 Double Solenoid Valve – NAND Gate | No | Yes |

| 40 | Introduction to UP / DOWN Counters | No | Yes |

| 41 | NOR gate operation with electrical switches to operate double acting cylinder | No | Yes |

| 42 | Operation of Air Motor with Timer using 3 way 2 position Single Solenoid Valve | No | Yes |

| 43 | Sequencing Of Two Cylinders ( A+ B+) ; (A- B-) | No | Yes |

| 44 | DA Cylinders A & B Move Forward And Reverse For 3 Cycles, Then Pneumatic Motor Operates For 5 Sec | No | Yes |

| 45 | Operation Of Double Acting Cylinder With Double Solenoid Valve With ON Time Delay | No | Yes |

| 46 | Operation of Double Acting Cylinder with Single Solenoid Valve With OFF Time Delay | No | Yes |

| 47 | Continuous Operation of Double Acting Cyl With Double Solenoid Valve snd DOWN Counter | No | Yes |

| 48 | Continuous Operation of Double Acting Cylinder with 5/2 Double Solenoid Valve and UP Counter | No | Yes |

| 49 | Sequencing Of Three Cylinders A+ B+ C+ , C- B- A- | No | Yes |

| 50 | Sequencing Of Three Cylinders A+ B+ C+ ( C- B- A- ) With Time Delay | No | Yes |

Hydraulic - Pneumatic Circuit Design and Simulation Software

IRAI Software Features

- Circuits can be simulated in the softwareCircuits can be simulated in the software

- Pneumatic Circuits can be designed / constructed in Automgen software

- The same circuits can be performed on Hytech – Pneumatic training kit directly through software

- Library of the software contains more than 4000 hydraulic components

- PLC ladder diagram can be designed and dynamically updated in Siemens / ABB / OMRON PLC

- Vital parameters such as flow rate / pressure can be tested at various points in the circuit

- Validity of Automgen software is Perpetual (Valid for lifetime)

Optional Accessories

- Pneumatic Wall Charts

- Classroom Teaching Material

- Basic Level

- Advance Level

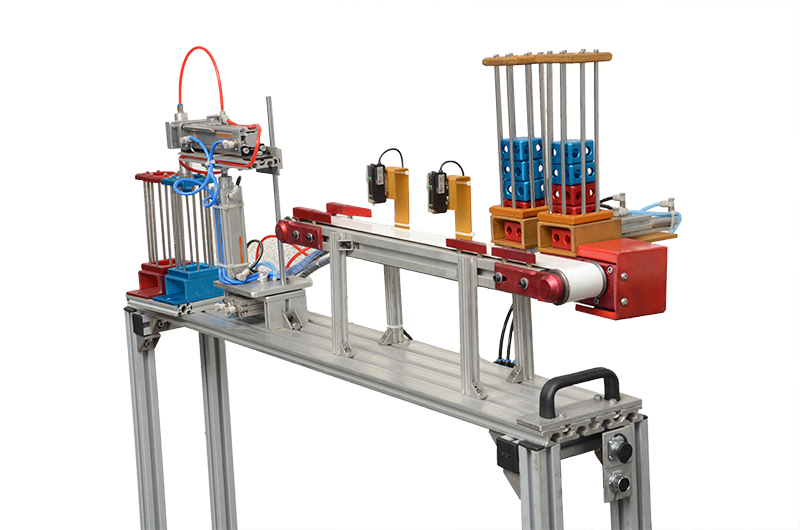

- Automation Modules

- Sorting Conveyor

- Press Application