CNC Mill Trainer

Features of CNC Mill Trainer:

- Can work on Mild Steel

- Can be used for light production work

- Industrial Tool Changer (For Semiproduction Machines)

- Being used in Reputed tool rooms across India such as MSME Agra, IDTR Jamshedpur, MSME Coimbatore, IGTR Ahmedabad, IGTR Aurangabad, MSME Mumbai

- Authorised Distributors for Fanuc India products

- Industrial controllers from Siemens and Fanuc

- Three Dimensional Simulation as well as dynamic machining

Prestigious Customers of CNC Mill Trainer:

- Maruti Suzuki Capability Development Center – Manesar

- IIT (Delhi)

- MSME Agra

- Indo German Tool Room – Ahmedabad

- Indo German Tool Room – Aurangabad

- Indo Danish Tool Room – Jamshedpur

- GCE Bilaspur

- NIT Warangal

- MSME Mumbai

- MSME Coimbatore

- Amity University – Greater Noida

Specifications of CNC Mill Trainer

| MT 250 | SMT 250S_Servo | |

| Axes | ||

| Axis Motor and Drive | Servo Motor with Servo Drives | Servo Motor with Servo Drives |

| X Axis | 300 mm | 300 mm |

| Y Axis | 225 mm | 225 mm |

| Z Axis | 250 mm | 250 mm |

| Ball Screw X / Y / Z | Ø25 x 5 – C4 Class | Ø25 x 5 – C3 Class |

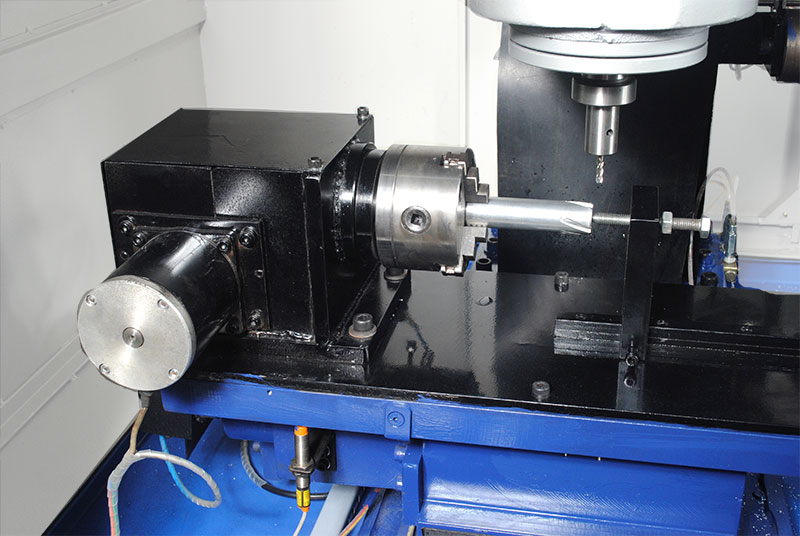

| 4th Axis Provision (Optional) | Provided | Provided |

| Distance between Table top and Spindle Nose | 70 – 370 mm | 70 – 370 mm |

| Distance between Spindle to Column | 270 mm | 270 mm |

| Feed Rate | 0 to 1,200 mm/min | 0 to 10,000 mm/min |

| Rapid Travel | 0 to 1,200 mm/min | 10,000 mm/min |

| Table | ||

| Table Size | 600 X 160 mm | 600 X 160 mm |

| T Slot | 3 x 10 x 50 | 3 x 10 x 50 |

| Load On Table | 120 Kg | 120 Kg |

| Spindle | ||

| Spindle Motor Capacity | 2 HP | 2 HP |

| Motor Type | AC Motor with VFD | AC Motor with VFD |

| Spindle Nose Taper | ISO 30 / BT 30 | ISO 30 / BT 30 |

| Spindle RPM | 100 to 3000 RPM | 100 to 3000 RPM |

| CNC Controller Details: | ||

| Controller | CutViewer-United Kingdom with Emulation of Fanuc, Siemens , Traub and Heidenhain |

CutViewer-United Kingdom with Emulation of Fanuc, Siemens , Traub and Heidenhain |

| Control System | PLC Based Control System | PLC Based Control System |

| Operating Software | CutViewer – United Kingdom | CutViewer – United Kingdom |

| Keyboard Type | Fanuc Emulated / Standard | Fanuc Emulated / Standard |

| Accuracy | ||

| Positioning | 0.015 mm | 0.005 mm |

| Repeatability | +- 0.010 mm | +/- 0.010 mm |

| Resolution | 0.010 mm | 0.001 mm |

| 4th Axis Resolution (Optional) | 0.02 Degrees | 0.02 Degrees |

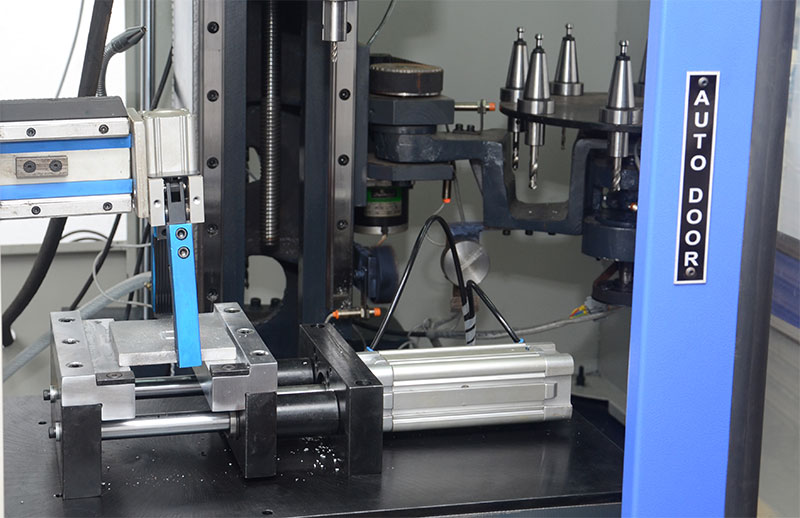

| Tool Changer (ATC) | ||

| Tool Changer | Automatic | Automatic |

| No. of Tools | 8 | 8 |

| Maximum Tool Length | 40 mm | 40 mm |

| Maximum Tool Dia. | 16 mm | 16 mm |

| Type of ATC | Umbrella Type | Umbrella Type |

| Actuation | Pneumatic / Hydraulic | Pneumatic / Hydraulic |

| Machine Details | ||

| Run Speed Control | Computer Controlled with Software | Computer Controlled with Software |

| Real Time tool path simulation | Provided | Provided |

| Vice Type | Pneumatic/ Manual | Pneumatic/ Manual |

| Compatible Softwares | MasterCAM, EDGE CAM, Solid Edge, BobCAD | MasterCAM, EDGE CAM, Solid Edge, BobCAD |

| Dimension in mm | 1540 x 1200 x 1700 mm | 1540 x 1200 x 1700 mm |

| Power Supply | 230V, Single Phase | 415V, +-2% 50 Cycles, 3 Phase |

- PLC based technology which is much more advances than PC (I/O Card)

- based technology generally used in trainer machines

- Emulation of Fanuc, Siemens , Traub as well as Heidenhain controller

- CAM Programs (NC Codes) Generated from any leading CAD CAM Software such as MasterCAM,

- NX CAM, Solidworks, Solid EDGE, EDGE CAM can bedirectly executed on the Hytech CNC Trainer Machines

- Servo Motors and Servo Drives from Mitsubishi / Siemens

- Indigenously designed & manufactured patterns & high quality FG32 grade castings

- Ergonomically designed machine

- 8 Station ATC (Automatic Tool Changer) with Pmeumatic Actuation

- Option of Linear Motion Guideways

- 4th axis arrangement with 4 axes interpolation

- Floor mounted machine with minimum weight of 1100 Kg

- C3 class ground ball screws

- Option of Pneumatic Vice

- Automatic Lubrication and Automatic Coolant

- Fanuc Emulated Industrial grade MOP

- Option of Metallic telescopic bellows

- Option of MPG (Manual Pulse Generator)

- AC Motor spindle with power ranging from 2HP to 5HP

- Air Mist Lubrication

- Provision of software as well as hardware overtravellimits to avoid any accident

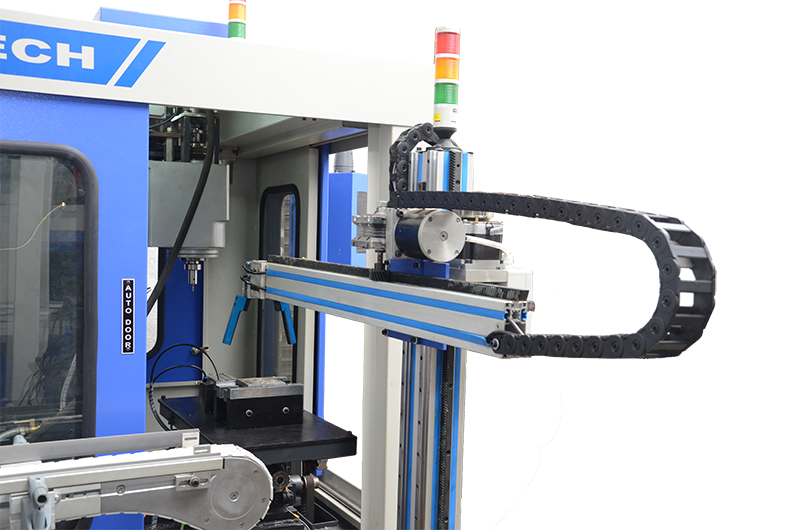

- Option of Automatic loading and unloading Arm (3 Axis Robotic Arm)